STAMP formula

how to customize hose

SIZE

Parker uses a system of measurement called Dash Numbers to indicate hose and fitting size. The Dash Number, or Dash Size, is the Measure of a hose's inner Diameter (I.D.) in sixteenths of an inch. (The exception to this is SAE 100R5 hose. See the chart below for complete details.)

This measuring system of the inside diameter of the hose is universally used by the fluid power industry today.

Don't know the hose size? Check the layline. If the original printing has worn off, the original hose must be cut and the inside diameter measured. Be sure to measure the overall assembly length and fitting orientation before cutting hose.

The hose ID. Must be sized accurately to obtain the proper glow velocity A flow that's too slow results in sluggish system performance, while a flow that's too high causes excessive pressure drops, system damage, and leaks.

Use the flow capacity Nomogram Section E to determine the proper hose I.D. for an application's flow rate requirements.

TEMPERATURE

When specifying hose, there are two temperatures you need to identify. One is the ambient temperature, which is the temperature that exists outside the hose where it is being used the other is the media temperature, which is the temperature of the media conveyed through the hose.

Very high or low ambient temperatures can have adverse affects on the hose cover and reinforcement materials, resulting in reduced service life.

Media temperatures can have a much greater impact on hose life. For example, rubber loses flexibility if operated at high temperatures for extended periods

Parker hoses carry different temperature ratings for different fluids. For example, the hose has a temperature range of -40F to + 257F (-40C to +125C) for petroleum based hydraulic fluids. However, for water, water /glycol, and water/oil emulsion hydraulic fluids, the range drops to a rating of up to +185F (+85C). Air is rated even lower at up to 158F (+70C)

Some media can increase or decrease the effects of temperature on the hose. The maximum rated temperature of a hose is specific to the media.

APPLICATION

Before selecting hose, it is important to consider how the hose assembly will be used. Answering the following questions may help.

- What type of equipment is involved?

- What are the environmental factors?

- Are mechanical loads applied to the assembly?

- Will the routing be confined?

- What about hose fittings permanent or field attachable?

- Will the assembly be subjected to abrasion?

Sometimes specific applications require specific hoses. For example, applications where hoses will encounter rubbing or abrasive surface, would be best handled by our family of abrasion-resistant hose with Gladiator cover.

When application space is tight, bend radius is another important consideration Parker offers full line of hoses increased flexibility and smaller outer diameter allows faster easier routing in small spaces, reducing both hose length and inventory requirements.

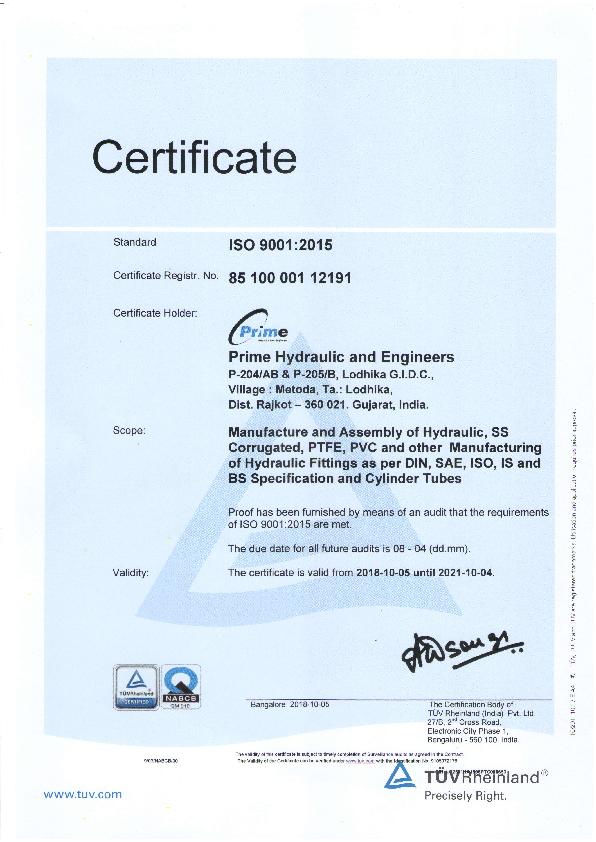

Industry standards set specific requirements concerning construction type, size, tolerances burst pressure, and impulse cycles of hoses. Parker hydraulic hoses meet or exceed standards such as:

- SAE (Society of Automotive Engineers)

- EN (European Norm)

- DIN (Deutsche Institute for Normung)

- ISO (International Standards Organization)

Governmental agencies control additional standards for particular industries such as D.G.M.S. You must select a hose that meets the legal requirements as well as the functional requirements of the application.

MEDIA

What will the hose convey? Some application requires the use of specialized oils or chemicals consequently the hose you order must be compatible with the medium being conveyed. Compatibility must cover not just the inner tube, but the cover, hose fittings, and o-rings as well. Use the Chemical Resistance Chart to select the correct components with a system's media. The chart contains the chemical resistance rating of a variety of fluids.

MEDIA

When considering hose pressure, it's important to know both the system working pressure and any surge pressures and spikes.

Hose selection must be made so that the published maximum working pressure of the hose is equal to or greater than the maximum system pressure. Surge pressures or peak transient pressures in the system must be below the published maximum working pressure for the hose.

Each parker hose has a pressure rating which cam be found on the hose a 4:1 safety factor unless otherwise noted Burst pressure rating for hose are for manufacturing test purposes only. They are nit an indication that the product can be used above the published maximum working pressure. It is for this reason that the burst pressure ratings have been remove from the hose chart within the catalog.

Care must also be taken when looking at the "weakest link" of the hose assembly. A hose assembly is rated at the maximum working pressure of the hose and the fitting component. Therefore the maximum working pressure of the hose assembly is the lesser of the rated working pressure of the hose and the end connections used.

A hose assembly (which consists of hose and two fittings) would have a maximum working pressure of the littlest of the three components. For example, the fittings have a 12,000 psi rating. The hose has a 5800 psi rating. Therefore the maximum pressure rating of the hose assembly would be 5800psi. Pressure ratings for each Parker end connection can be provided on request.